Air compressors have become an indispensable tool in various industries. With their ability to compress air and produce high-pressure airflow, air compressors are used in a variety of applications, from manufacturing to construction. In this article, we will look at the history of the development of air compressors , from the beginning of their discovery to the modern technology we know today.

1. Early Development of Air Compressors

In the 17th century, Dutch physicist Christiaan Huygens was one of the pioneers in the development of air compressors . In 1650, Huygens created the first piston air pump capable of producing a pressurized air flow. Although still simple, this laid the foundation for further inventions and developments in air compressors .

2. Centrifugal Compressor

In the early 19th century, attention turned to the development of centrifugal compressors. British engineer George Medhurst developed the centrifugal compressor in 1799. This compressor used a rotating rotor to produce a pressurized air flow. This technology provided the advantages of high speed and smaller size compared to conventional piston compressors.

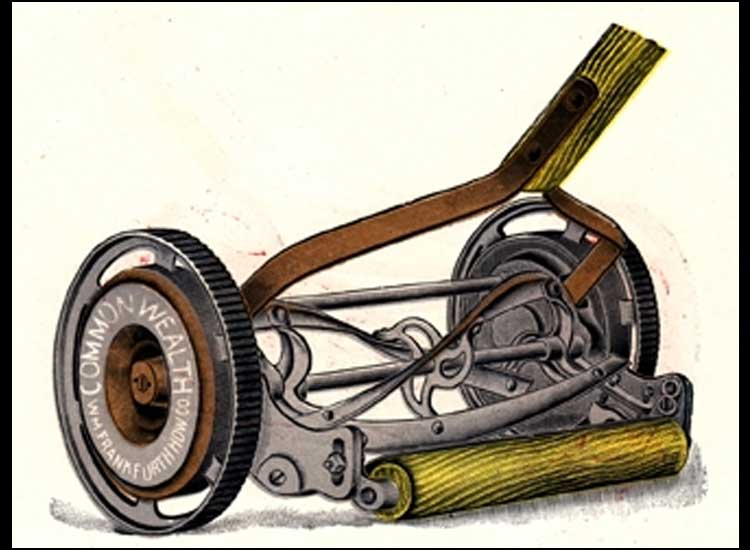

3. Compressor Piston

Although centrifugal compressors have advanced air compressor technology, piston compressors remain the preferred choice for many applications. In the mid-19th century, German mechanics Wilhelm Maybach and Gottlieb Daimler developed a portable piston compressor for use in the railroad industry. Piston compressors have continued to improve in performance and efficiency as engine technology has advanced.

4. Refrigerated Compressor

In the late 19th century, the invention of the refrigerated compressor became an important milestone in the history of air compressors . French engineer Albert Carré discovered that by using low-pressure gas as a working medium and compressing it adiabatically, he could produce high-pressure air with better efficiency. This technology later developed into refrigerated compressors that are widely used in the oil, chemical, and gas industries.

5. Kompresor Scroll

In 1905, the scroll compressor was invented by Swedish engineer Carl Munters . This compressor uses two spirals that interact with each other to produce compression. Scroll compressors are smaller in size, lower in noise, and higher in efficiency compared to conventional piston compressors. This technology allows air to be compressed continuously and produces a steady air flow. Scroll compressors are commonly used in air conditioning systems, air conditioners, and small to medium industrial applications.

6. Kompresor Rotary Screw

In the 1930s, the rotary screw compressor was invented and became a major breakthrough in the air compressor industry. Developed by German engineer Alf Lysholm and later refined by American engineers Frederick Boge and Philip Drucker, the rotary screw compressor combines two rotating rotors with a special profile to produce compressed air. The advantages of the rotary screw compressor are high efficiency, consistent airflow rates, and more compact size . This type of compressor is widely used in the manufacturing, construction, and automotive industries.

7. Centrifugal Compressor with Inlet Guide Vanes (IGV)

Air compressor technology continued to advance with the introduction of centrifugal compressors with inlet guide vanes (IGVs) in the 1950s. IGVs are adjustable vanes at the compressor inlet to control the inlet airflow. This allows for better control of pressure and airflow, as well as increased compressor efficiency. Centrifugal compressors with IGVs are widely used in the power, petrochemical, and natural gas industries.

8. Kompresor Variable Speed Drive (VSD)

In the 1980s, variable speed drive (VSD) compressors became a breakthrough in the air compressor industry. VSD compressors use electric motors that can be adjusted to speed, producing airflow according to demand. This reduces energy consumption and extends the life of the compressor. VSD compressors are especially efficient in variable load situations, where air demand changes over time. This technology is widely used in manufacturing industries that require precise control of airflow.

Conclusion

The development of air compressor technology from scroll compressors to VSD compressors has brought significant changes to the industry. Higher efficiency, smaller size, and better controllability have provided great benefits to various sectors. With continued innovation, air compressors will continue to play an important role in supporting production processes, energy efficiency, and environmental sustainability in the future.

In the digital era and industry 4.0, air compressors are increasingly connected to smart systems and data management platforms. This allows for performance optimization, better maintenance planning, and better integration with production systems and other systems as a whole.